Posted by Ondrej M on 22nd Feb 2025

Building the dream - Part 2 Engine rebuild

Rebuilding the engine: My Year-Long DIY Honda S2000 Restoration Journey

In the previous chapter, I introduced myself, the car, and outlined the plan. I have decided to split the rebuild project into chapters—they might not all be in chronological order, but I thought organizing them this way would make it easier to navigate through the project and perhaps easier for you, as a reader, to follow the progress.

The car has covered roughly 110k miles, and although there were almost no issues with the engine—yes, I said almost—that will soon become very important.

When I mentioned that I bought the car in 2011 with 80k miles and was very happy with its condition, there was a hidden secret lurking in the engine—a secret that decided to reveal itself just six months later. This issue would become an important and expensive part of the rebuild during this project.

Whoever had been servicing the car before me did not follow proper torque specifications and either cross-threaded or over-tightened a spark plug into the cylinder head. This is my theory, as I have never heard of F20 engines having issues with spark plugs. Well, this mistake caused the spark plug to blow out of the cylinder head, setting the ignition coil on fire.

Luckily, the timing of this failure was fortunate—it happened just as I was arriving home from work and parking in front of my house. Just a few days earlier, we had been touring the Netherlands, and I had forgotten to buy European breakdown coverage, which would have covered returning the car to the UK. That could have been a disaster.

To wrap up this story—I visited a Honda dealership, probably just for fun, only to be told that they would have to organize a specialist skeleton crew to fix the engine, as the dealership did not typically handle these types of repairs. Other quotes I received were around £2,000, with shops explicitly stating that there would be no warranty on the work. I couldn’t justify spending that much, although I don’t feel like the garages were trying to rip me off.

This left me with only one option—my first-ever attempt to rebuild a cylinder head myself. I took the head to a specialist engineering shop, where they replaced the damaged thread with a thread insert, ensuring that the new thread was even stronger than the original. Just a couple of weeks later, the car was back on the road, and I was happy again.

Fast-forward 10 years…

As I mentioned earlier, this will be important later.

With that backstory out of the way, we can now focus on the current project, as some of my decisions will now start making more sense.

The engine has been hoisted out and placed on a rotary engine stand, ready to be stripped down. The parts list for the engine can now begin—one of many lists, one of many orders, and one of many... "Oh, I forgot to order that part" moments.

Upgrades Overview

This is probably a good point to outline the list of upgrades as well:

- Oil baffle pan – Screw-on from Ballade Sport

- Upgraded oil jet squirters – Mine were still 2-port instead of 4-port (I believe there was also a recall from Honda for this upgrade)

- Upgraded chain tensioner – Ballade Sport (Although I don’t have any issues yet, when I fitted the Toda one to my friend’s car, it felt like much better quality—at least, that was my impression.)

- Lightweight flywheel – Not super lightweight, just slightly lighter

- Aftermarket radiator – Koyorad (Not that the original one was inadequate, but it looked a bit tired, and I quite like the look of the aftermarket one.)

I didn’t want to enhance the engine’s performance—just make small changes to improve reliability and perhaps prepare it for some light track use.

As part of the refresh:

- Almost all rubber hoses were replaced—whether oil, air, or fuel hoses. 22-year-old rubber wasn’t something I wanted to keep in the car.

- All fuel pipes – Luckily, I managed to get genuine Honda ones.

- Both engine mounts

- All chains

- All gaskets that I could find

- All hose clips – Either restored or bought new.

- All bolts, nuts, washers, and brackets – Either new or restored.

- New cylinder head (I’ll come back to that later.)

- New valves, springs, and valve retainers – Since I was already fitting a new cylinder head, I decided not to reuse the old ones.

- New valve cover – I was running out of time, so instead of restoring the original one, I just bought a new one.

- New ignition coil cover – Gold to confuse people, as that was originally from the 2.2L AP2 engines.

- New intake-side camshaft – The original had rust pits due to the car not being driven often, which meant the oil hadn’t circulated regularly.

Time to strip everything down to just the engine block. I'm not sure I can call this complete engine rebuild as I have decided not to touch the crank shaft and pistons, reason being the cylinder walls were nice and smooth, the engine never smoked, not consumed more oil than it's normal and the oil always remained gold color. I have therefore decided not to touch them.

The engine block has been cleaned though and I have also cleaned the tops of the pistons to remove all carbon deposits and test fitting the bolt on oil baffle plate.

Remember when I mentioned that the cylinder head had been repaired with metal inserts? Well, as I removed the spark plugs, one of the threads decided to come out with the spark plug, and no matter what I tried, I couldn’t get it back in.

This made me think about the future—would I go back to the engineering shop, have the inserts fitted again, and possibly face the same issue a few years later? This question was haunting me, and after a quick search, I decided not to take any chances.

"Just order a new cylinder head," my mind was telling me. Luckily, I was able to find a brand-new head directly from Japan through Amayama. This shop quickly became my go-to place for almost all my parts—and for good reason. I was able to get genuine brand-new Honda parts for half the price (or even cheaper) than at a UK Honda dealer. Even after factoring in delivery costs from Japan, import taxes, and fees, I was still saving a huge amount of money.

What’s more, the delivery times were around two weeks, whereas Honda UK had back-ordered parts that took months—for the exact same parts.

To give you an example:

- The cylinder head cost around £1,500 from Amayama, while the UK main dealer was asking £3,500 for the same part.

- The valves and almost all other parts followed a similar pricing pattern.

- Some O-rings that Honda dealers priced at over £30 per piece were available for just $1 each with the same part number.

For a project like this, keeping an eye on costs is crucial. No, this isn’t a budget build, but at the same time, I don’t want to take out a second mortgage just to complete it.

Although buying all the parts new would have been quicker, as I mentioned earlier, I had to keep an eye on costs. This led me to build an electroplating station, allowing me to not only clean all screws and brackets but also restore their corrosion protection with a long-lasting layer of zinc and nickel plating.

For this, I used a high-power lab power supply so I could carefully control the voltage and current.

I had to set up pre-wash, acid etching, electrolysis, catalyst, and final wash baths, which pretty much meant ending up with several 10L buckets for each step. I’m not going to paint a rosy picture—this process was quite challenging from the start, especially for someone who had never done it before. However, I prevailed and didn’t give up.

Once I had all the screws and brackets ready, rebuilding the engine could finally begin.

There was just one more thing to do—replace the bearings in the belt pulleys. But, of course, being me, I didn’t just swap out the old bearings. Instead, I removed them, sandblasted the pulleys in my small cabinet blaster, repainted them, and only then pressed the new bearings in.

New chains, guides, gaskets and other parts.

If Ikea has ever sold cars, this is what I would imagine the flat pack engine would look like.

Now, adding all of that together, we arrive at the final result. I know I haven’t documented every step of the process, but there is already an amazing resource available online—the Honda S2000 workshop manual. It’s an absolutely fantastic guide and a must-have handbook for a project like this.

The engine is now almost complete and looks like new. This is also thanks to the replacement of the plastic cable sleeve with a brand-new one.

There has also been another important wiring upgrade—I installed a thicker wire from the alternator, a new wire for the starter motor, and a thicker ground wire. If I had kept everything stock, this wouldn’t have been necessary, but this will be important for the sound system.

Yes, your eyes aren’t deceiving you—I said sound system. I will dedicate an entire chapter to the sound system, so there’s more to come on that topic.

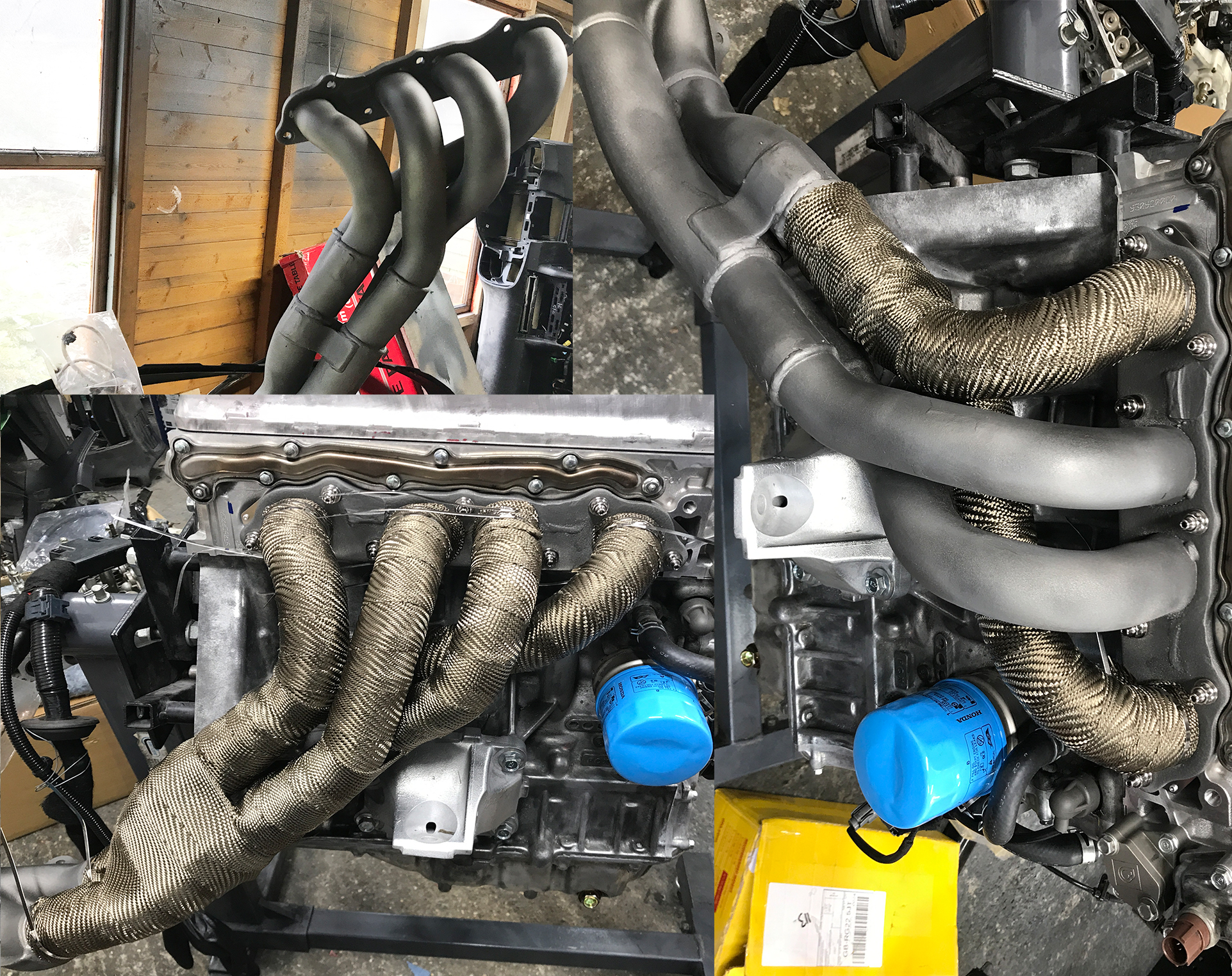

As a nice finishing touch, I decided to wrap the exhaust manifold. I don’t think it will improve performance, but it definitely looks aesthetically cool—and yes, I did dent the oil filter.

Hope you enjoyed the images, and if you’re still hooked, that’s it for now! The engine can be set aside, and in the next chapter, I will be restoring the fuel tank, refurbishing the subframes, and creating my own solid brake lines from marine-grade stainless steel.